INNOVATIVE APPROACH

- More Than 145 Years in the Design, Engineering, and Construction of Complex Facilities.

- Responding to Ever-Increasing Compliance Constraints.

- Flexibility to Support Multiple Product Line Change.

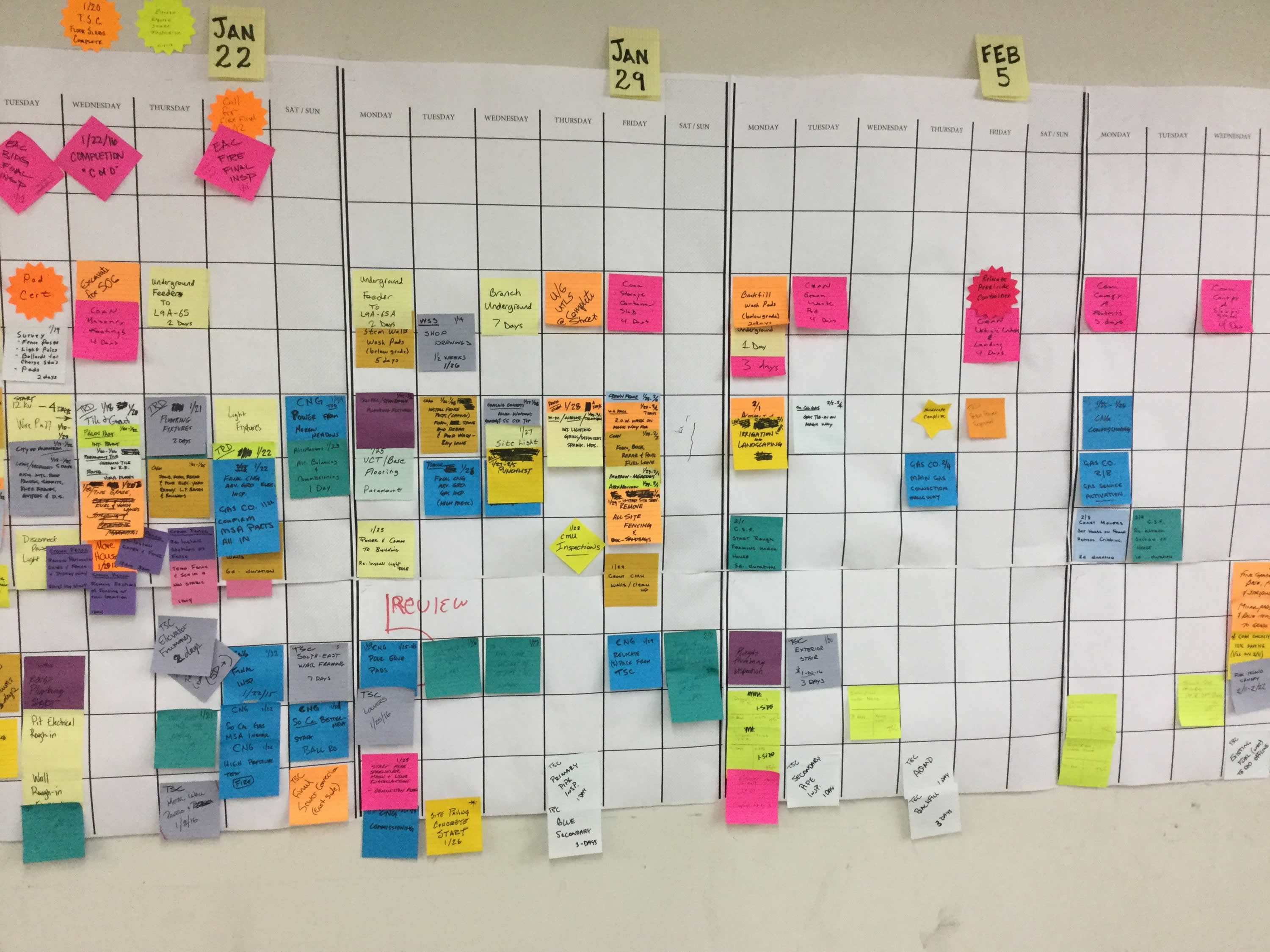

ON TIME AND BUDGET

- Front-End Planning.

- Establishing a Fixed Cost Early in the Process.

- Reducing Clients’ Exposure to Risk.

- Providing Single-Source Responsibility.

- Reducing Change Orders and Schedule Delays.

LOCATION CONSULTING

SERVICES

SERVICES

- Location Strategy Studies.

- Favorable Area Analysis.

- Labor Market Studies.

- Property Due Diligence.

- Incentives Negotiation.

- Strategic Master Planning.

- Manufacturing And Feasibility Studies.

PHARMACEUTICAL TECHNICAL CENTER

The Austin Company provided architecture and engineering services for an R&D technical center for Hospira, an international pharmaceutical company.

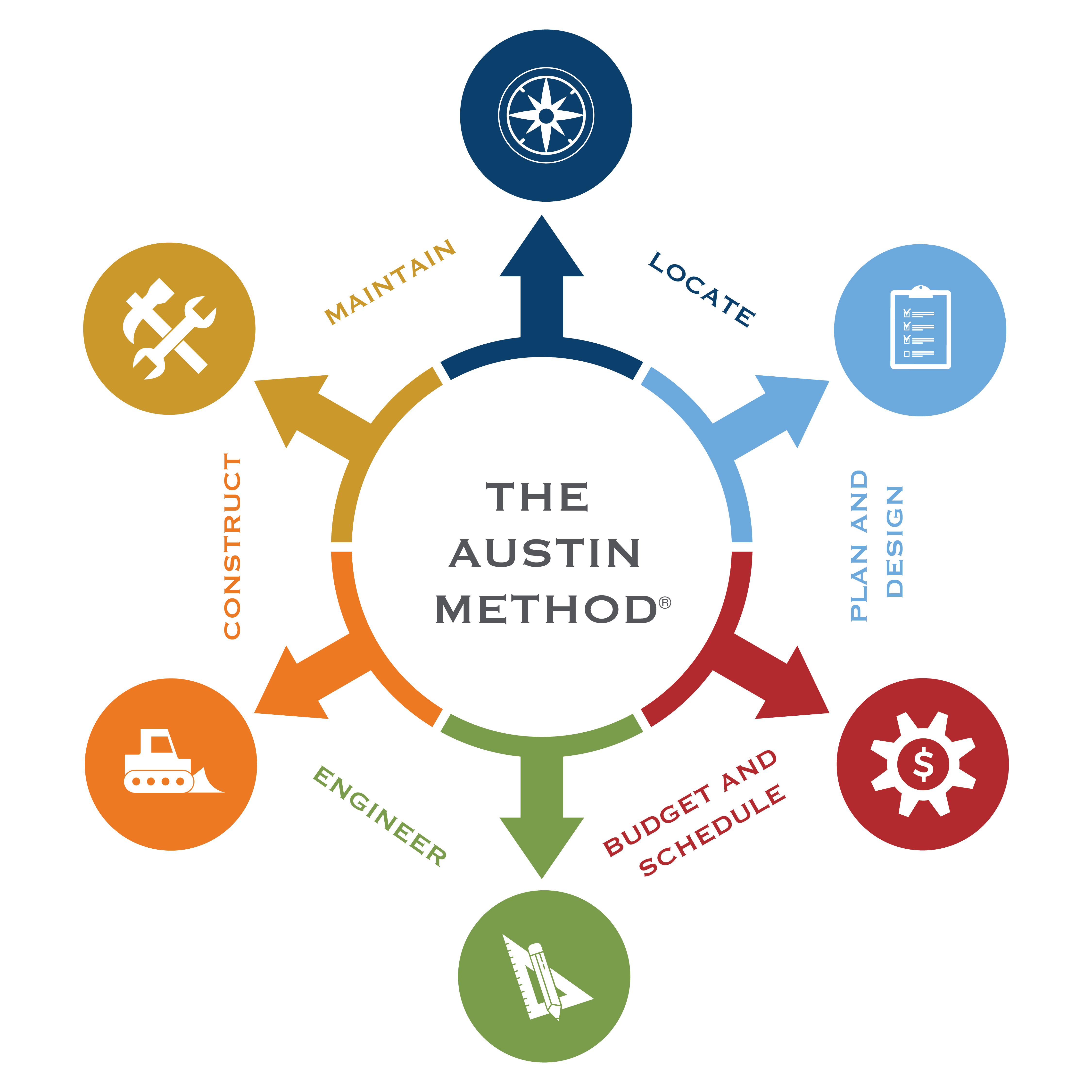

THE AUSTIN METHOD®

The Austin Method is the proprietary design-build method developed in 1901 to provide clients a single-source for the design, engineering, and construction of a project. Austin can provide services from start to finish—or any step in between—to meet the client’s objectives for a project on time and within budget.

Austin offers multiple approaches in implementing a project. These generally can be classified into either a design-bid-construct or design-build project approach. In addition, Austin offers The Austin Method, which applies stringent project controls and combines the advantages of “design-bid construct” and “design-build” approaches into a competitive bid, cost-effective, and accelerated-schedule project implementation.

TO LEARN MORE ABOUT OUR PROJECTS FOR MEDICAL DEVICES AND PRODUCT PRODUCTION, VIEW OUR PROJECT GALLERY