DEDICATION TO SAFETY

Safety is imperative and utility companies across the United States set specific engineering standards for safety at their plant support facilities. These standards exceed typical building standards that are required by codes today.

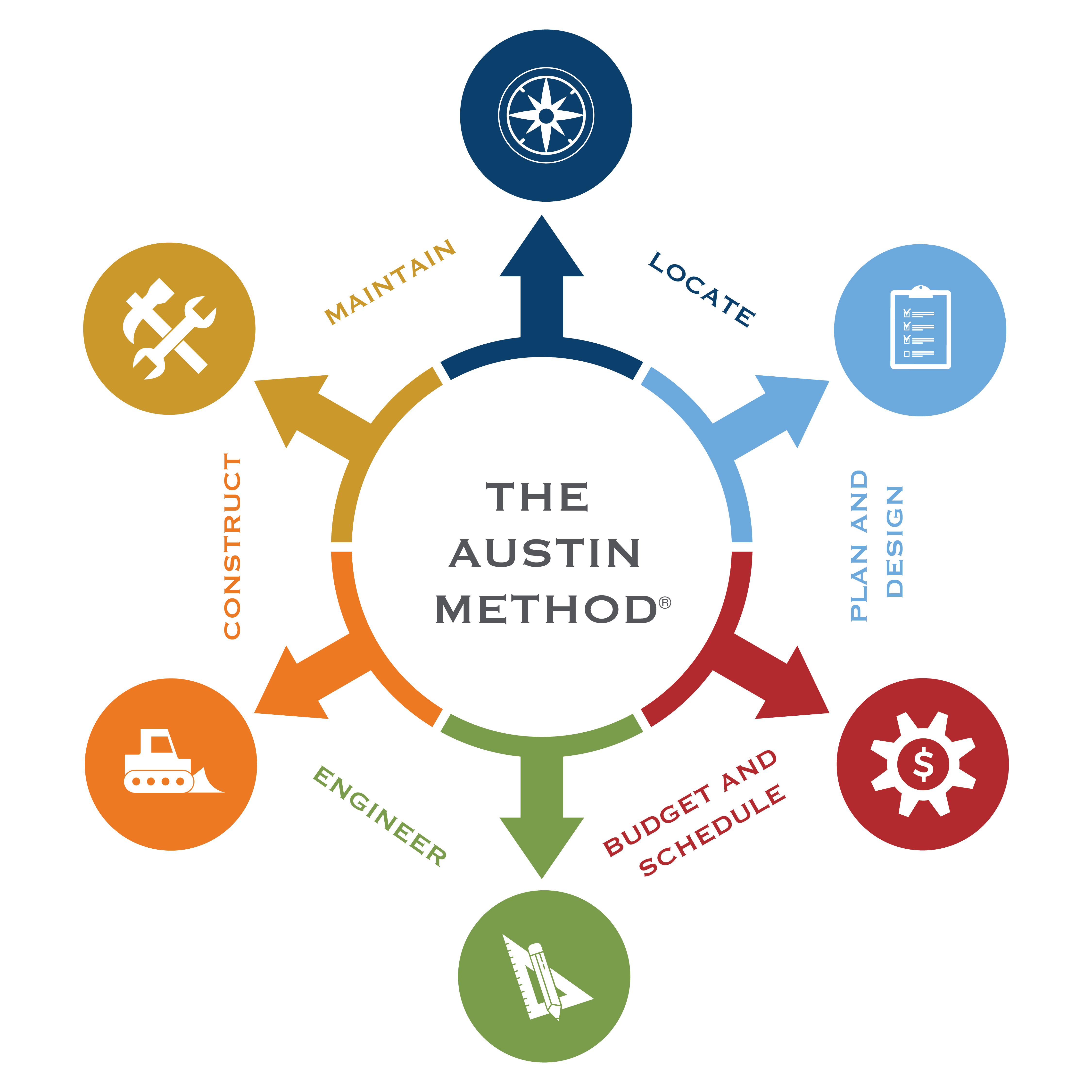

THE AUSTIN METHOD®

The Austin Method is the proprietary design-build method developed in 1901 to provide clients a single-source for the design, engineering, and construction of a project. Austin can provide services from start to finish—or any step in between—to meet the client’s objectives for a project on time and within budget.

Austin offers multiple approaches in implementing a project. These generally can be classified into either a design-bid-construct or design-build project approach. In addition, Austin offers The Austin Method, which applies stringent project controls and combines the advantages of “design-bid construct” and “design-build” approaches into a competitive bid, cost-effective, and accelerated-schedule project implementation.

TO LEARN MORE ABOUT OUR NUTRACEUTICAL PROJECTS, VIEW OUR PROJECT GALLERY