DESIGN AND ENGINEERING SERVICES

- Site Planning and Conceptual Design.

- Mechanical, Electrical, Structural, and Plumbing Engineering.

- Fire Protection Engineering.

- Process Engineering.

- Process Equipment and Piping Design.

- Process Instrumentation and Controls.

- Waste Water Treatment Design.

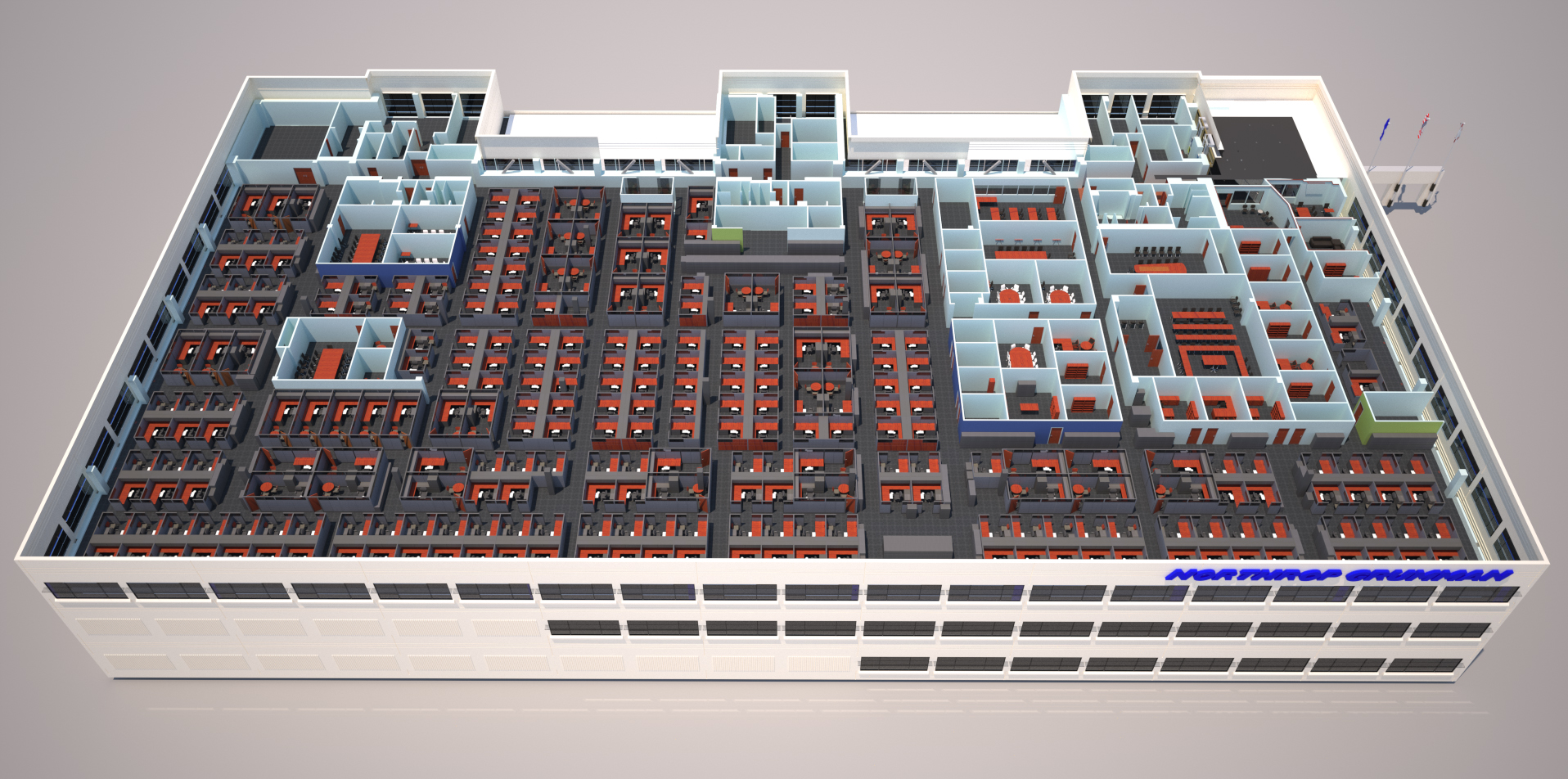

VIRTUAL DESIGN AND CONSTRUCTION

- Reduced Risk.

- Streamlined Data Workflows.

- Clash Detection.

- Leveraging of Model Information.

- Increased Efficiency.

- Increased Collaboration and Coordination.

- Improved Decision-Making.

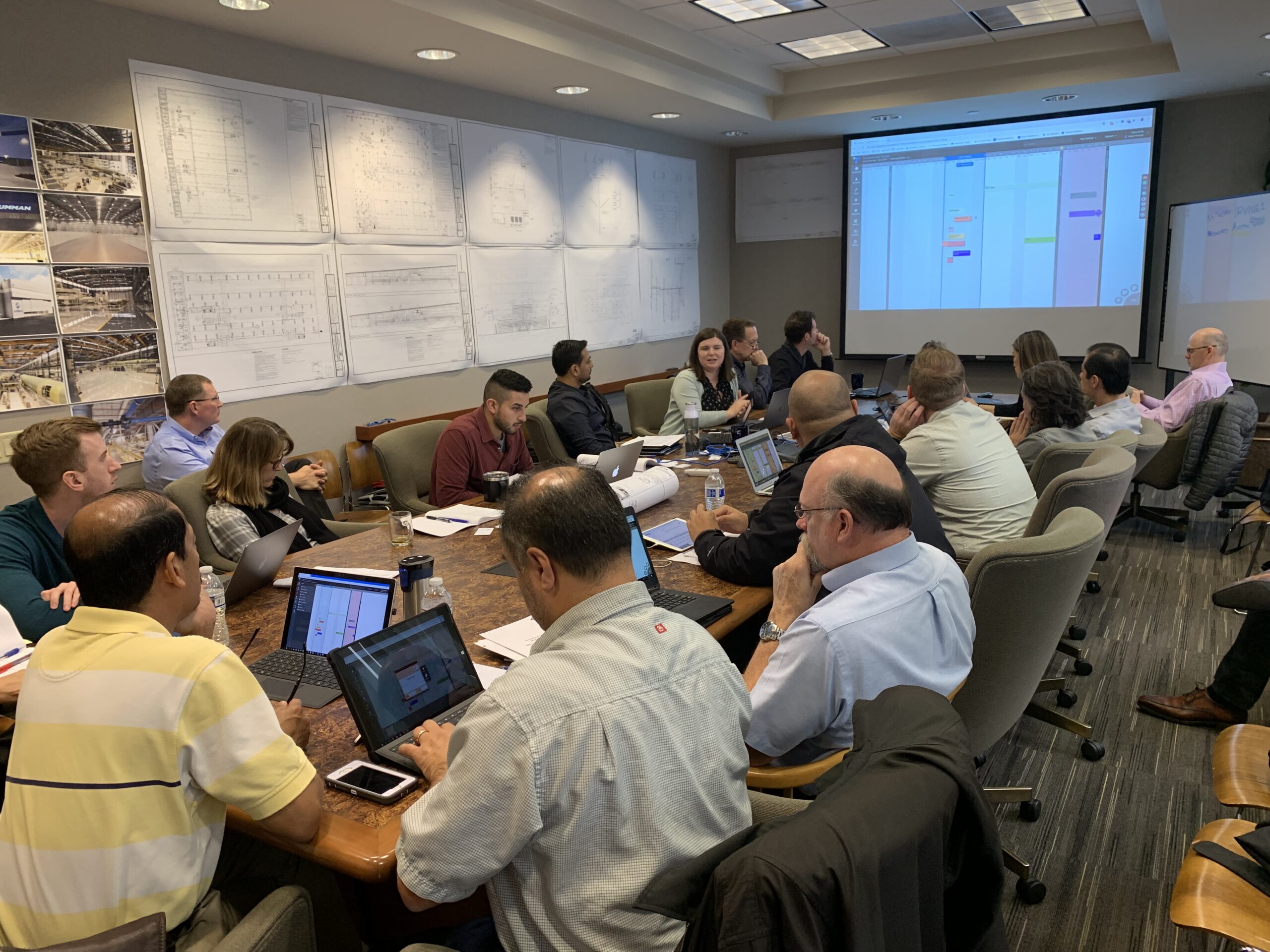

LEAN DESIGN AND CONSTRUCTION

- Improved Productivity and Cost Savings.

- Reduced Safety Hazards.

- Improved Coordination Among All Project Team Members.

- Optimization of Budgets, Including Life-Cycle Costs.

- Potential for Earlier Completion.

PEPPERIDGE FARM BAKING AND SNACK PRODUCTION FACILITY

Pepperidge Farm’s Goldfish® crackers were introduced in the 1960s and today continue to be a family favorite. Two decades of sustained growth prompted Pepperidge Farm to expand its cracker production operations in Richmond, Utah.

TO LEARN MORE ABOUT OUR BAKING AND SNACK PROJECTS, VIEW OUR PROJECT GALLERY