PACKAGING CONSIDERATIONS

- Integrated Team Works to Address Critical Packaging System(s).

- Scope and Functional Requirements.

- Equipment Selection Assistance.

- Construction, Installation, Commissioning, and Start-Up.

THE AUSTIN METHOD®

- Location Consulting.

- Incentives Planning and Negotiation.

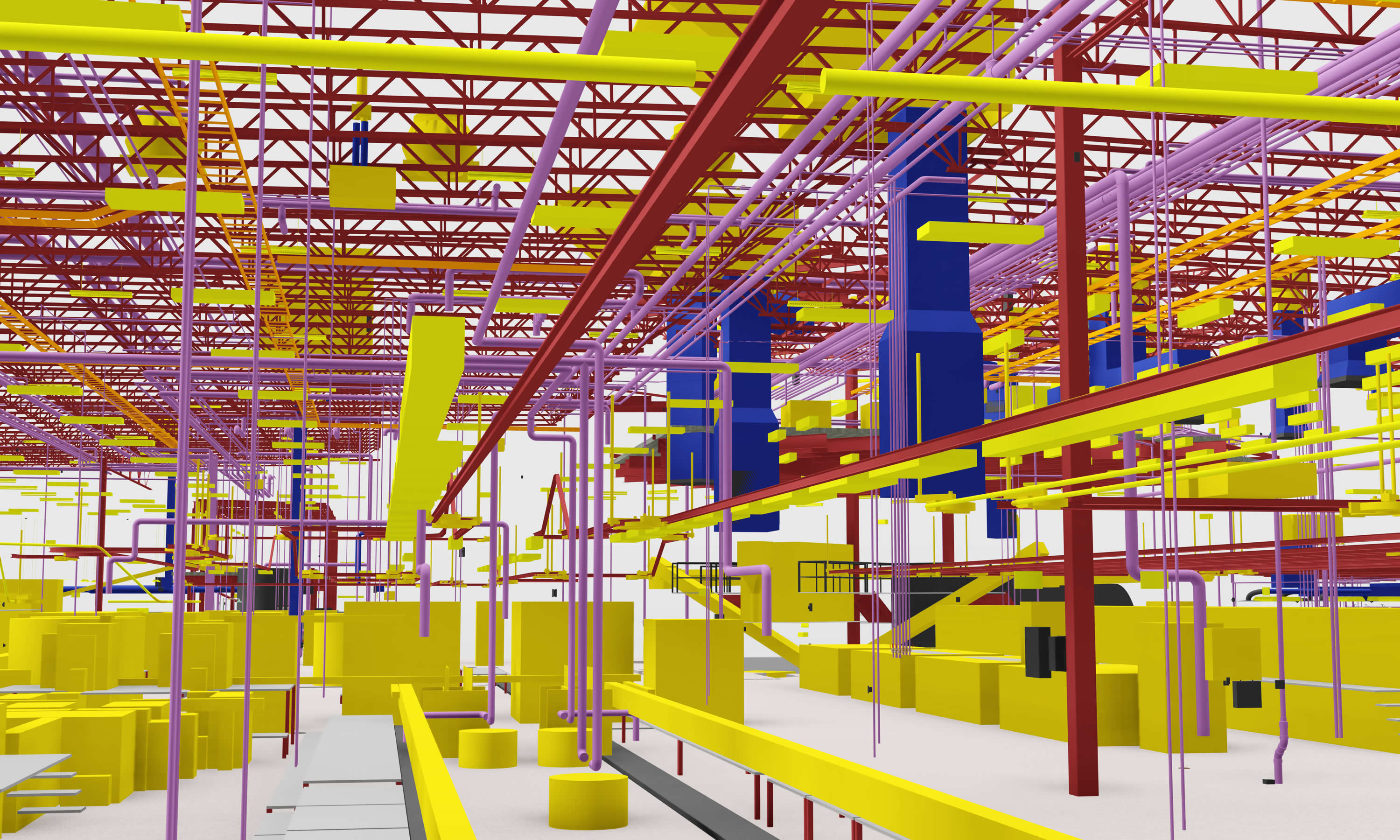

- Preconstruction.

- Design and Engineering.

- Construction.

- Facility Maintenance.

PROCESSING FOR FOOD AND CONSUMER GOODS

- Production and Packaging Plants.

- Refrigeration Systems.

- Automated Distribution and Bulk Storage Warehouses.

- Research Labs.

- Wastewater Treatment Systems.

COLGATE-PALMOLIVE TOOTHPASTE MANUFACTURING FACILITY

Colgate-Palmolive, a global leader in oral care, solicited The Austin Company to provide site location consulting, and design and build a new state-of-the-art, 250,000 SF dental cream facility in Morristown, Tennessee.

TO LEARN MORE ABOUT OUR FOOD AND CONSUMER GOODS PROCESSING PROJECTS, VIEW OUR PROJECT GALLERY