EXACT MEASURES OF EXPERIENCE AND EXPERTISE

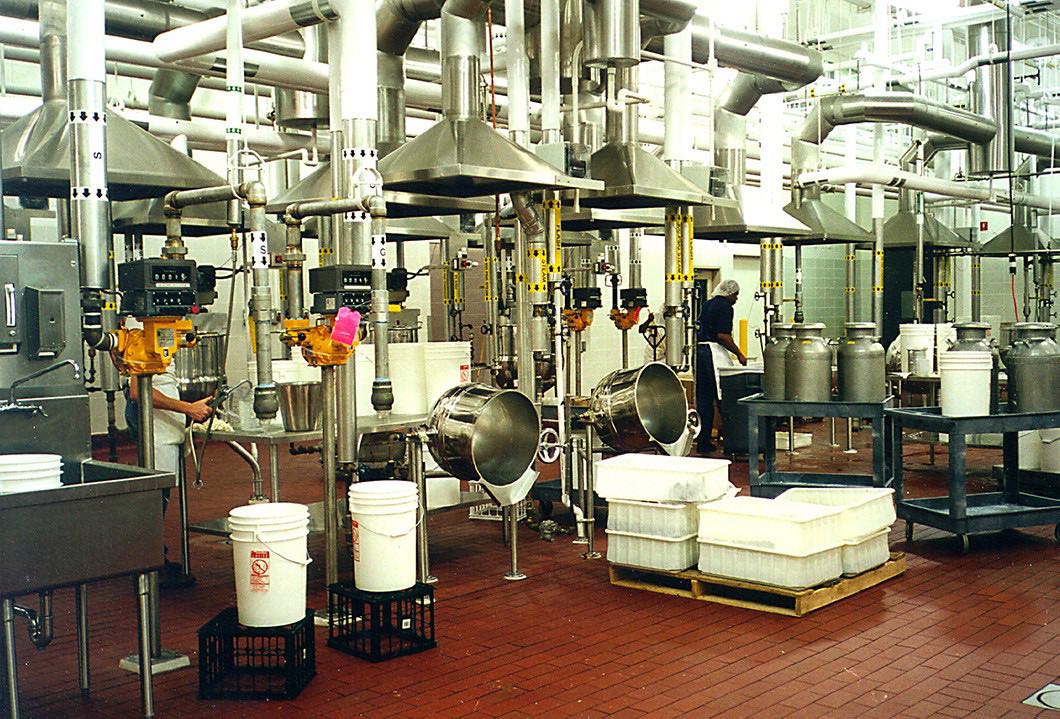

It’s the consistency of following a unique recipe that sets your product apart. Every ingredient is measured precisely; each step in the process is exact. Dedication to every detail ensures success, batch after batch, line after line.

We know confectionary equipment and the processes: from starch moguls and the circulation of liquid chocolate, to cooling tunnels and high-speed custom packaging machines.

We know the industry trends: the need for increased automation and for more attractive, brighter work areas that help recruit and retain employees.

We know the challenges you face: new products and the rush to market; plant expansions that must not interrupt current production; and always, adherence to food safety.

Austin’s fully integrated team uses a stepped approach known as The Austin Method® which begins with preliminary design, followed by preliminary engineering, then detailed engineering and construction. This stepped approach ensures we do it right the first time and could shave months off the schedule for a large manufacturing plant.

THE AUSTIN METHOD

Single-Source Responsibility For All Design-Build Services

- Engineering.

- Construction Management/General Contracting.

- Location Strategy.

- Site Selection.

- Due Diligence.

- Incentives.

- Planning.

- Procurement.

- Estimating.

- Scope Control.

- Start-Up and Commissioning.

- Facility Maintenance.

- Development and Financing.

FAST-TRACK SOLUTIONS

We Excel at Fast-Track Projects, Offering Faster Results With Lower Cost and Higher Quality, and Successfully Delivering These Solutions:

- Finding the Optimum Greenfield Site or Existing Building for Conversion.

- Design and Engineering of the Process and Building.

- Construction.

- Confectionary Processing Equipment, Piping, Controls, Instrumentation Selection, and Integration.

- Wastewater Treatment.

PLANT DESIGN APPROACH

Total Team Collaboration From Architectural Design Through Construction Brings Your Facility From Concept to Completion

Innovative solutions to support these operating requirements:

- Raw Materials Storage.

- Packaging System Design.

- Construction.

- Building Envelope and Roof Systems.

- Utilities, Controls and Refrigeration.

- Water Flow.

- Sustainability.

- Plant Safety and Security.

TO LEARN MORE ABOUT OUR CONFECTIONARY PROJECTS, VIEW OUR PROJECT GALLERY

RUSSELL STOVER CANDIES CONFECTIONARY MANUFACTURING FACILITIES

Russell Stover Candies turned to The Austin Company on multiple occasions for major facility projects, including new construction and major expansions.