VIRTUAL DESIGN AND CONSTRUCTION

- Reduced Risk.

- Streamlined Data Workflows.

- Clash Detection.

- Leveraging of Model Information.

- Increased Efficiency.

- Increased Collaboration and Coordination.

- Improved Decision-Making.

FAST-TRACK SOLUTIONS

- Finding the Optimum Greenfield Site or Existing Building for Conversion.

- Design and Engineering.

- Construction.

- Confectionary Processing Equipment, Piping, Controls, Instrumentation Selection, and Integration.

- Wastewater Treatment.

Plant Design Approach

- Raw Materials Storage.

- Packaging System Design.

- Construction.

- Building Envelope and Roof Systems.

- Utilities, Controls, and Refrigeration.

- Water Flow.

- Sustainability.

- Plant Safety and Security.

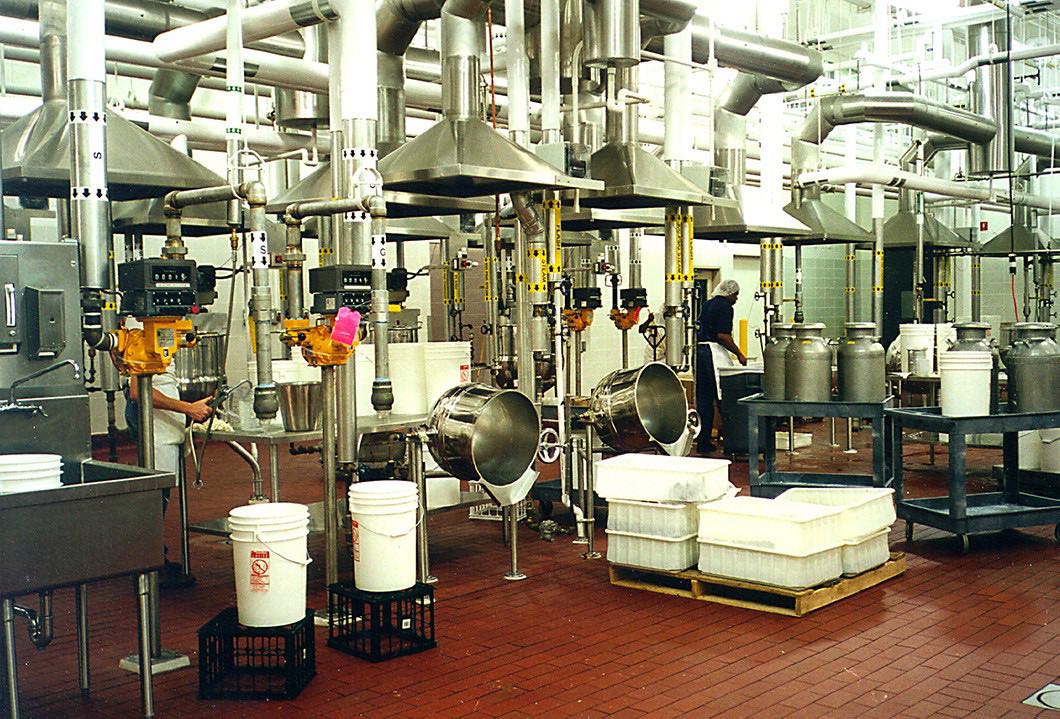

RUSSELL STOVER CANDIES CONFECTIONARY MANUFACTURING FACILITIES

Russell Stover Candies turned to The Austin Company on multiple occasions for major facility projects, including new construction and major expansions.

TO LEARN MORE ABOUT OUR CONFECTIONARY PROJECTS, VIEW OUR PROJECT GALLERY