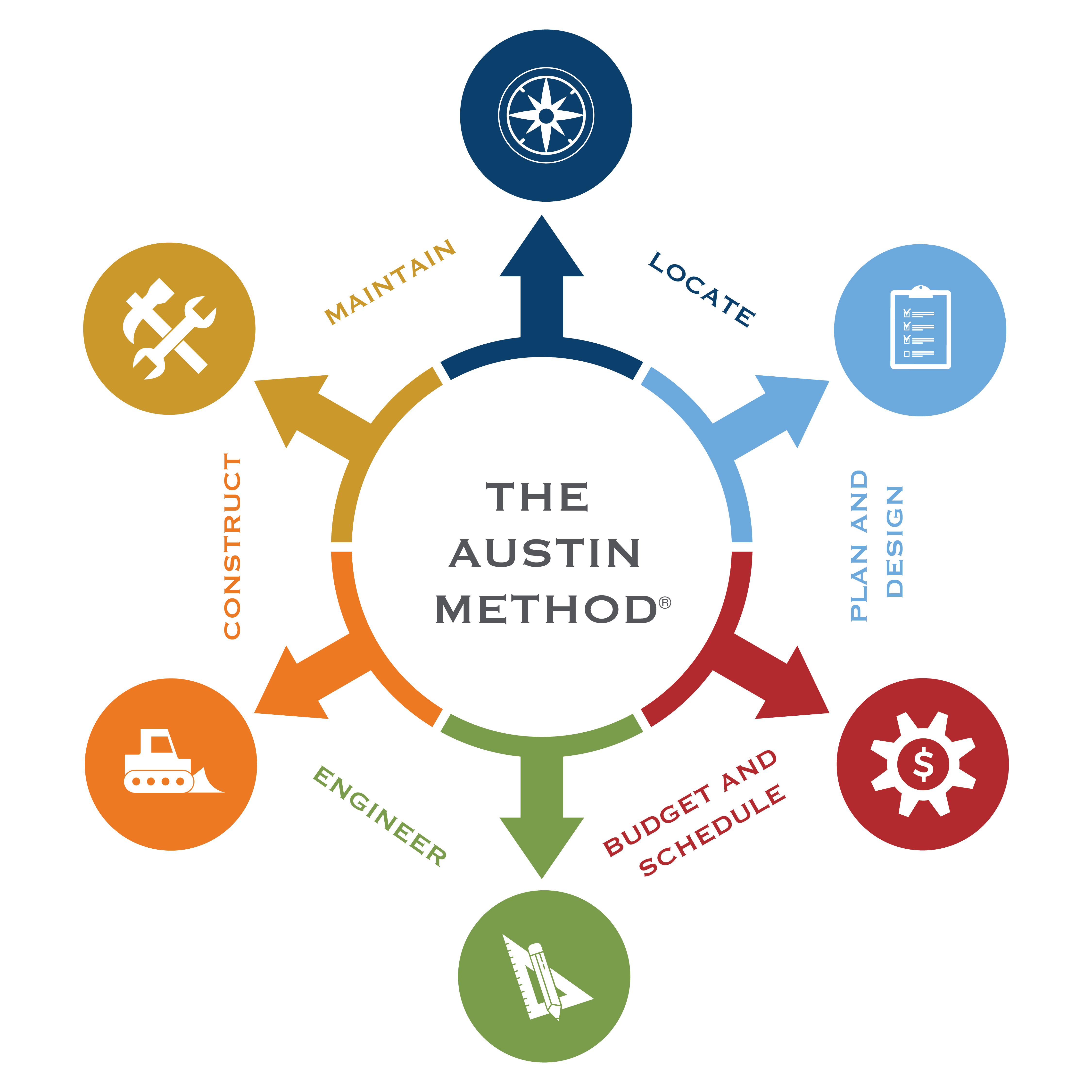

THE AUSTIN METHOD®

The Austin Method is the proprietary design-build method developed in 1901 to provide clients a single-source for the design, engineering, and construction of a project. Austin can provide services from start to finish—or any step in between—to meet the client’s objectives for a project on time and within budget.

Austin offers multiple approaches in implementing a project. These generally can be classified into either a design-bid-construct or design-build project approach. In addition, Austin offers The Austin Method, which applies stringent project controls and combines the advantages of “design-bid construct” and “design-build” approaches into a competitive bid, cost-effective, and accelerated-schedule project implementation.

TO LEARN MORE ABOUT OUR LAB AND CLEAN ROOM PROJECTS, VIEW OUR PROJECT GALLERY