Benefits of Precast Double T Concrete Beams in Structural Floor and Roof Systems

Construction professionals know that reinforced concrete, as a building material, offers unique benefits to structures. Buildings made of reinforced concrete are incredibly robust, exhibit outstanding performance in corrosive environments, and possess inherent fireproofing capability.

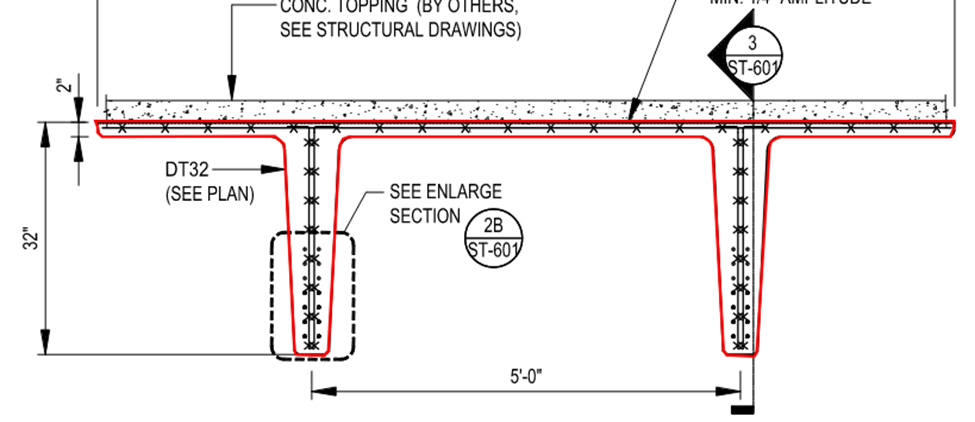

A special type of reinforced concrete structural element is the precast double T concrete beam (double-T beam), which is used as a vertical support element in floor and roof systems. A double-T beam is cast in a factory in a sectional shape that resembles two “T”s joined together – hence the name “double-T” (see Figure 1). The double-T beam offers superb cleanliness due to the elimination of dust-collecting horizontal surfaces, making them ideal candidates for buildings with clean production needs as in some food and medical devices manufacturing.

This system also allows for long spans of more than 60 feet and thus is often chosen for buildings requiring voluminous column-free space (like parking garages and open manufacturing plants). Furthermore, the double-T beam concrete allows for superior longevity even in harsh building interior conditions (such as steam exposure).

The vertical stem of the T makes it hard for conduit and lighting to be routed, so it’s very good for facilities where there is enough headroom for process utilities and lighting to be placed below the T and above the ceiling.

Precast vs. Cast-in-Place Factory workers prepare long double-T-shaped casting beds in a linear assembly.

Cast-in-place construction refers to concrete structural elements cast at the location of the final position in the building. The double-T beam is precast in a factory and fabricated off-site in a factory. It is shipped to the project site, where it is set into its final building position. Precast construction allows for superior fabrication quality control and important beam-strengthening operation known as prestressing to take place. As the name suggests, prestressing is a factory operation that applies a “pre-force” onto the beam before the application of building loads. The prestressing operation is critical to provide the double-T beam with adequate strength and stiffness to support significant loads over long spans. The prestressing operation is generally completed as follows:

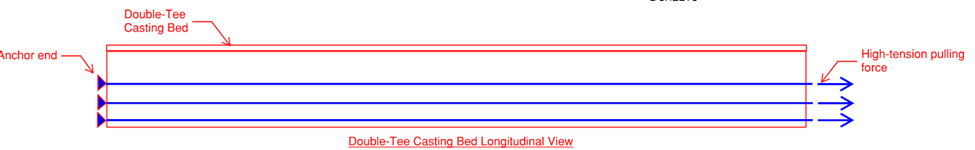

Factory workers prepare long double-T-shaped casting beds in a linear assembly.

Workers position reinforcing into the casting beds per the Structural Designer’s details and specifications.

Workers will pre-tension special types of high-strength reinforcement called “strands” which have been placed into the casting beds. The pre-tension operation occurs by anchoring one end of the strands to the casting bed, and then pulling on the strand from the far end with a hydraulic jack, producing tens of thousands of pounds of tension in the strand (see Figure 2).

Concrete is then poured into the casting beds with the strands held in high tension.

When the concrete has cured, the external pulling force in the strands is removed. The strand immediately attempts to shrink back to its unstretched shape – but it is now restrained along its length by the newly cast concrete. This permanent tension in the strand thus manifests as a stabilizing compression force in the double-T beam (the prestressing force).

Creating the Roof Structure

A typical length of a double-T beam is 70 ft long by 10 ft wide. The beams typically also have an upwards camber due to the prestressing operation. These beams are shipped from the factory to the project site on truck beds. Cranes at the project site latch onto the double-T beams at pick points and lift and set them to their final positions in the building. As the positioned beams begin to support building loads, the prestress is induced upward, and the camber flattens to a horizontal level.

The robust double-T beams have a relatively large area (700 SF for a 70 FT long x 10 FT wide beam), so large areas of floors and roofs are quickly constructed as the beams are erected into place.

An important component of most double-T beam floor and roof assemblies is the cast-in-place concrete topping diaphragm. The topping is a thin layer (typically 2-1/2 to 4 inches thick) that provides a level horizontal surface across the entire floor or roof and acts as a structural “diaphragm” (A structural diaphragm is a thin, stiff plate that provides lateral stability to the structure when it is subject to seismic and wind forces). During the factory production process, grooves are fashioned across the tops of the double-T surfaces; the cast-in-place topping concrete keys into these grooves and allows the topping and precast double-T to act compositely (in unison) to resist the superimposed floor or roof loads.

Maintenance-free

Precast concrete requires little to no maintenance after installation. By contrast, steel assemblies often require patching, repair, and reapplication of fireproofing, insulation, and any paint coatings.

Special Considerations for Precast Concrete

Precast double tees are unique products that are built by precast concrete companies. Typically, the precast concrete company is subcontracted by the general contractor for a project. The distance of the closest precast concrete plant to the project will dictate the cost of shipping to the project site. However, in most locations throughout the United States, precast concrete elements can be shipped at competitive prices. Here are a few important considerations for using double-T beams for your project:

- Concrete Super-Structure. Double-T beams are optimally connected to concrete girders, concrete columns, and concrete walls. All these supporting building components are typically precast (in a factory and shipped to the site), but it is feasible to cast-in-place (use formwork to cast the members at their final position). Either way, it is important to remember that double-T beams are typically part of overall concrete buildings.

- Shipping. As discussed, precast double-T beams need to be shipped to the job site. So, the location of the closest precast concrete company, shipping costs, and shipping schedule need to be factored into the overall project scope.

- Installation. Concrete double-T beams and other concrete precast elements are heavy (typical single element weights can be 25 Tons or more). Crane selection, crane staging, and construction site safety plans are critical aspects for the design and construction team to assess and plan.

A client’s unique needs are always at the forefront of our design process. To learn if precast concrete roofing is right for your project, reach out to our team.

|

DONNA LORENZEN, PEDIRECTOR OF ENGINNERING AND DESIGNCall 949.451.9960 | Email Donna | View Profile |