Time is a valuable commodity. For design-builders with single-source responsibility, mapping out the time it will take for each component of the project and having an organized plan are crucial to meeting the client’s needs.

Nirav Mehta, Austin’s Western Operations architectural and engineering design project manager, believes that the 30/60/90 day deliverable schedules developed at the start of a new project only tell part of the story. With the pressure to get projects completed as soon as possible, especially those with quick turnaround deadlines, engineering schedules are often compressed.

At first glance, the accelerated 30/60/90 day milestones can seem overwhelming to an engineering team. Mehta explains that the introduction of new software called Touchplan allows engineers a more practical focus on the individual tasks within those milestones, especially those they can begin immediately.

“Our general manager has already used this tool on a construction project with great success,” he says. “We were excited about adapting its capabilities to engineering.”

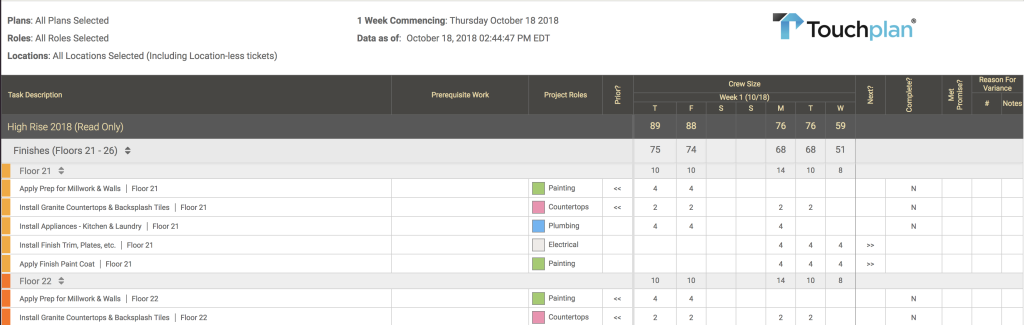

Touchplan is a web-based collaboration tool based on lean construction principals. The tool transforms the traditional sticky note pull planning process and connects the team digitally, providing real-time updates for greater efficiency and communication.

Mehta has found the program is excellent to help design teams—as well as construction teams—identify critical milestones, define a work plan, look ahead to identify potential constraints, increase accountability, and focus on continual improvement.

Austin’s Western Ops has used Touchplan for several months now, and team members are becoming more adept at maximizing its features. The Weekly Work Plan and the Percent Promised Complete features are particularly helpful to engineers, Mehta states.

The Weekly Work Plan is a report of To-Do tasks that are to be completed before the next weekly meeting. Mehta says the report serves both as a meeting recap and to identify specific tasks for each team member.

The Percent Promised Complete report keeps track of the number of promised tasks that are complete. This report helps identify whether a team is meeting its deadlines or if it needs additional support to do so. It also reveals when a team is ready to assume other tasks.

Weekly Touchplan meetings promote communication between individual members of the team and the client. Using the tool to review task lists allows the engineers to see the sequence of events required and where communication can move the project ahead.

Mehta gives the example of an electrical engineer who might need to determine the placement of outlets in a room. To accomplish this, the engineer must have a layout of the room. However, the room layout cannot be sent to the electrical engineer until the client approves it. Touchplan allows the engineer to see on screen this opportunity for communication to move the project ahead.

Typically, delayed tasks are identified through these weekly meetings. As a result, a separate meeting can be held to determine how the engineering team can work to get the project back on schedule. By identifying the delay, the team can craft their solutions to reach the milestone date.

“Team members are encouraged to login daily to update tasks. Then during the weekly meeting, you can check off completed tasks. And for the tasks that are still open, you can determine if other issues have come up or if you’re waiting on information,” Mehta continues. “Once you know that, you can then plan tasks for the next week. Touchplan helps keep things on track. If you see things slipping, you schedule the necessary meetings to stay on track.”

Mehta feels that adapting this new program to engineering provides new opportunities for the team to fine-tune their processes. “Austin is always focused on meeting and exceeding clients’ expectations. Touchplan is another tool to help us do that on every new project.”

This article was first published in Results Magazine, a publication by The Austin Company.